How the Shipping Container Industry is structured and organized...

Shipping Container Manufacturing And Distribution

Although the ISO Container got its conception and started through American ingenuity, the United States had no ability to either build shipping containers economically or the ships to carry them.

The first shipping containers were manufactured by Japan, Europe, Korea, Hong Kong, and Taiwan. Those countries accounted for about 90% of all shipping container production.

The world needed less expensive shipping containers, and by the early 1980s China was surging rapidly as a global manufacturer of many products and commodities. Not only was China booming as a global exporter, but they had become one of the largest international manufacturers of steel.

Photo: Green Quest Research

China Takes The Lead

China entered the shipping container manufacturing business in 1980 with the formation of CIMC in Shenzhen, China, but only gained its greatest momentum beginning in 1993. Not only was China's low labor cost an issue, but China was also becoming the largest producer and recycler of steel. By 1995, even Taiwan, Hong Kong, Japan, Korea, and most of Europe were producing their shipping containers in Mainland China.

Since 1996, CIMC has been the largest manufacturer of ISO Containers in the world, and by 2007, China was producing 82% of the entire world supply of ISO shipping containers. There are now many smaller companies manufacturing in China that fabricate the ISO Containers in competition with CIMC.

Now, whether you see a shipping container from China Shipping, Maersk, Hapag-Lloyd, Evergreen, OOCL, Cronos, Hyundai, Hamburg, or any other shipping company, they are all still made in China.

Even though many companies such as Travelodge and Tempo Housing Keetwonen prefer new and specially designed ISBU modules from China factories they are still recyclable and very Eco-Green housing units

Container Manufacturing And Distribution

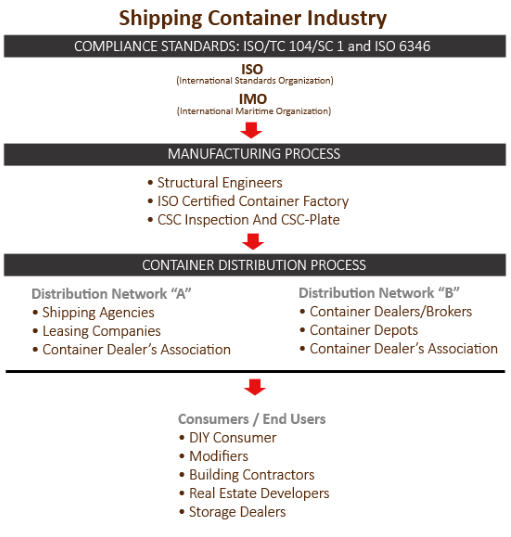

There are many levels in the ISO Container Industry, similar to the manufacture and distribution levels of automobiles, large electronics, appliances, and other large products.

The four (4) very basic levels of the container industry are Compliance, Manufacturing, Distribution, and Consumer.

Graphics: Green Quest Research

Shipping Container Manufacturing and Compliance

• ISO Maritime Compliance and Manufacturing Standards

The organization that sets these standards is called the IMO, meaning International Maritime Organization.

All 'container modules' manufactured for the purpose of shipping via the seas, ocean, or rail are required to be manufactured according to ISO Maritime standards set forth by the IMO, and then CSC certified.

This IMO Standard is not always necessary for 'container modules' manufactured specifically as an ISBU module.

Manufacturing Process

• Structural Engineers

• ISO Certified Container Factory

• CSC Inspections and CSC-Plates

Most Shipping Companies, Leasing Companies, and Container Distributors do not have their own manufacturing facilities. Most of these companies simply contract with a Steel Fabricator that specializes only in the manufacturing of 'shipping containers', 'ISBU modules', and related components. For example, when a Shipping Agency orders shipping containers, the Container Manufacturer already knows the basics of the product. They only allow minimal modifications from the IMO Standards.

Such modifications may include, additional structural strengths, wall corrugation types, flooring types, paint colors, locking systems, venting, company logos and usually two choices of wall steel thickness.

Minimum quantities of 100 units are standard, with additional price breaks in larger quantities.